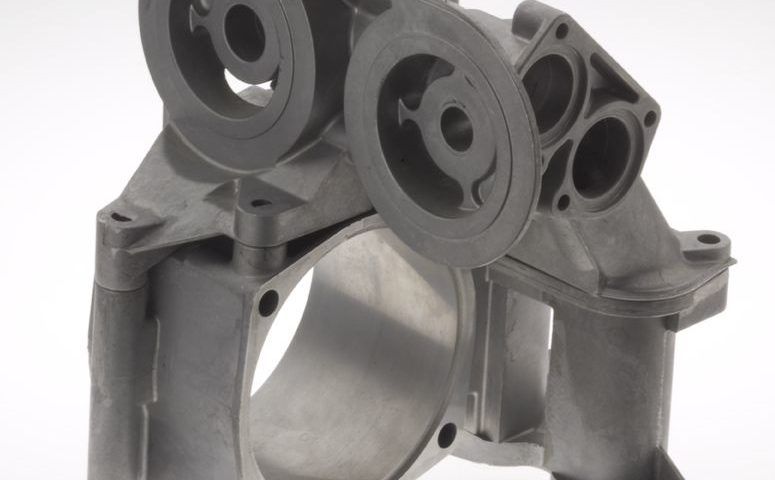

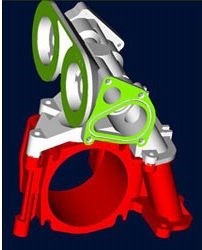

Aluminium cooling system for the nautical industry

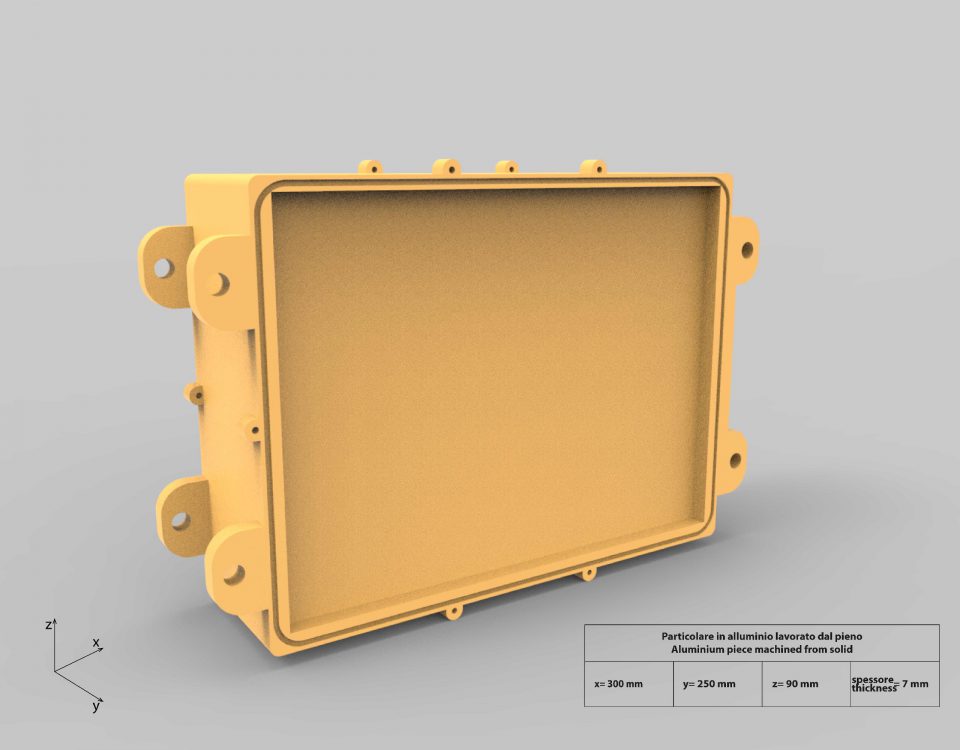

Aluminium casing for the telecommunications industry

26 December 2018The manufacturing and economic requirements of this product led us to re-examine the design, coming up with an unconventional solution.

In this case, the production process – which included sand-casting and machining – resulted in excessive costs and wastage due to porosity.

The solution, which was proposed and then implemented, consisted in a complete redesign of the part in order to manufacture it through die-casting. We made two parts from one, significantly reducing weight and the areas to be machined, which led to a notable reduction in production costs.

The entire project paid off in less than 18 months, despite the significant investments in moulds.